In bulk material handling systems, idlers operate under constant exposure to some of the harshest industrial environments—dust, water, abrasive materials, and extreme temperatures. The most common point of failure in an idler is its bearing assembly, where contamination and lubricant loss inevitably lead to costly breakdowns.

The key to idler longevity lies in one critical component: the sealing system. An idler is only as good as its seal.

Douglas Rulmeca’s PSV Idler features an advanced hybrid sealing system, combining the best attributes of contact and non-contact seals into a single, highly engineered design. This hybrid seal arrangement, combined with a hermetically sealed bearing cavity, offers unmatched protection, dramatically extending idler life and reducing maintenance requirements in even the most aggressive material handling applications.

The Engineering Challenge of Idler Sealing

Idler sealing systems face a difficult balance:

- Exclude contaminants such as fine dust, slurry, water, and abrasive particles

- Retain grease within the bearing cavity for proper lubrication

- Minimize rolling resistance to maintain energy efficiency

Conventional idlers often sacrifice one of these performance areas to improve another, resulting in premature bearing failure or increased conveyor energy consumption. The Douglas Rulmeca PSV Idler breaks this compromise through a hybrid seal design engineered to provide comprehensive protection without trade-offs.

PSV’s Hybrid Seal Design: The Best of Both Worlds

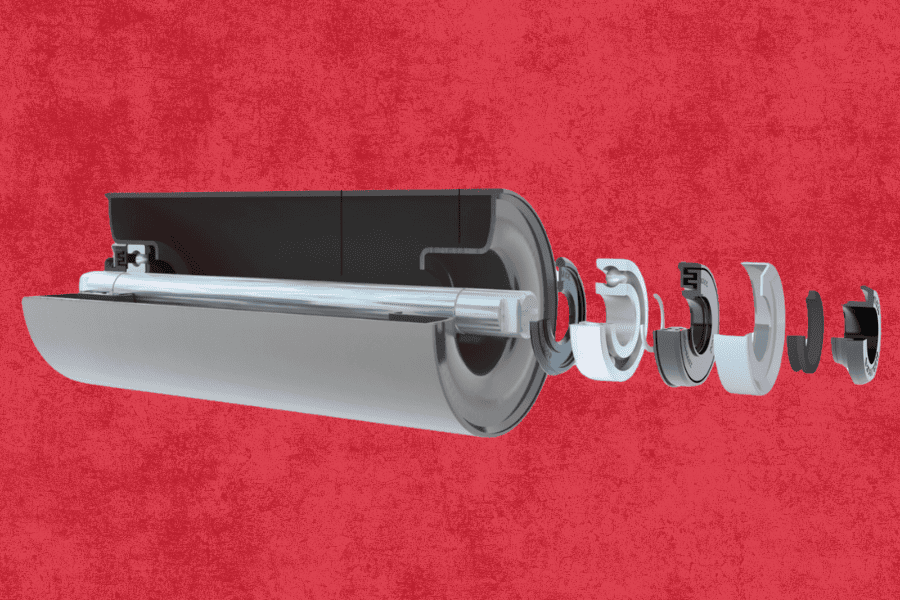

At the core of the Douglas Rulmeca PSV Idler’s superior performance is its hybrid sealing arrangement, uniquely combining non-contact labyrinth elements with high-efficiency contact seals.

Non-Contact Labyrinth Seal

- The first line of defense, a precision-machined labyrinth seal, creates a complex path that disrupts and blocks the ingress of large particles, dust, and moisture.

- Non-contact design ensures no friction is generated, maintaining low rolling resistance while providing robust contaminant exclusion.

- Serves as a pre-filter, preventing bulk material from ever reaching the sensitive inner zones of the idler.

Grease-Packed Intermediate Cavity

- Located between the labyrinth and contact seals, this grease-filled chamber acts as both a secondary barrier and a contaminant trap.

- Captures and neutralizes fine dust or moisture that passes the labyrinth.

- Maintains a ready supply of lubrication to the contact seal surfaces, preventing dry running.

Heavy-Duty Contact Seals

- Dual contact seals engage inside the housing, physically blocking microscopic contaminants.

- These seals retain grease within the bearing cavity, ensuring long-term lubrication and protection.

- Carefully engineered to minimize friction while ensuring positive sealing pressure against contamination.

Result: Hybrid Seal Performance

By combining the low-drag efficiency of a labyrinth seal with the positive closure of contact seals, the PSV hybrid seal system delivers maximum defense against environmental exposure while maintaining conveyor efficiency. It solves the traditional weakness of single-method sealing approaches.

Hermetically Sealed Bearing Chamber: True Isolation

Beyond its hybrid seal geometry, the Douglas Rulmeca PSV Idler features a hermetically sealed bearing compartment—a critical advancement in idler design.

What Does Hermetically Sealed Mean?

- The bearing cavity is fully enclosed and isolated from external air, dust, and moisture.

- Factory-filled with high-performance grease and permanently sealed, eliminating the need for field relubrication.

- No external vents or breather holes—preventing pressure differentials that could draw contaminants inward.

Benefits of the Hermetically Sealed Design:

- Absolute Contamination Prevention: No pathway for fine particulates or water to reach the bearings.

- Lubrication Integrity: Grease remains clean and effective for the entire service life of the idler.

- Zero Maintenance: No greasing points reduce labor costs and eliminate operator error.

- Extended Bearing Life: Protects against both physical contaminants and moisture ingress, the two leading causes of bearing failure.

The hermetic seal transforms the PSV Idler into a maintenance-free component, ideal for high-capacity, continuous-run systems where downtime is costly and access for routine maintenance is limited.

Superior Performance Across Demanding Applications

The PSV hybrid sealing and hermetic system have been proven effective in the most challenging operational conditions:

- Mining operations handling coal, iron ore, copper, and other abrasives

- Aggregate and quarry sites with high dust and impact loads

- Cement plants and ports exposed to corrosive and moist environments

- Power plants managing ash, wet slurry, and chemical exposure

In each case, the PSV idler’s sealing system prevents the typical contamination-driven failures that shorten the life of standard idlers.

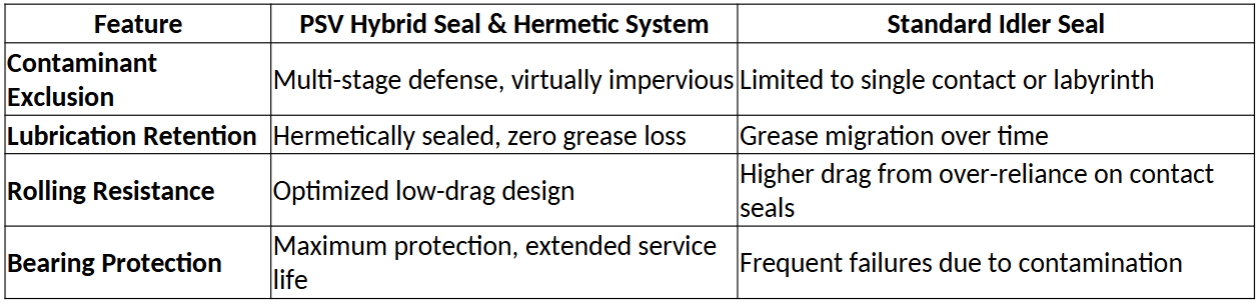

Comparative Advantages Over Conventional Idlers

The PSV system sets a new benchmark, particularly for long overland conveyors, remote installations, and operations where idler reliability is mission-critical.

Total Cost of Ownership Benefits

While the initial investment in a PSV Idler may be marginally higher, the lifecycle cost savings are substantial:

- Fewer idler replacements

- Reduced labor for maintenance

- Improved conveyor energy efficiency

- Minimized risk of belt damage from seized idlers

In high-tonnage operations, these savings translate directly into increased uptime, productivity, and profitability.

Conclusion: The Industry’s Best Sealing Solution

The Douglas Rulmeca PSV Idler represents the most advanced sealing technology available for bulk material handling conveyors. Its hybrid sealing system perfectly balances the need for low rolling resistance with robust contaminant exclusion. Coupled with a hermetically sealed bearing chamber, the PSV idler delivers unmatched protection, true maintenance-free operation, and extended service life.

For any operation seeking to maximize conveyor reliability, reduce operating costs, and eliminate idler-related failures, the Douglas Rulmeca PSV Idler is the clear solution—engineered for durability, designed for performance.

For further insights or technical specifications on the PSV Sealing System benefits and attributes contact Douglas Rulmeca.

Recent Comments